Actuator: different techniques

To control the organs and limbs of a robot, a series of technologies are being used.

How to animate a robot?

Piezoelectric properties are exploited by the electrostatic actuator. A ceramic rod lengthens in proportion to the voltage applied to the poles at both ends. This technique is used to actuate the print heads of ink jet printers. It seems more devoted to small objects and could move micro-robots.

You can make a actuator on this principle. The ceramic is formed of polymer-metal ion which have the property to deform at very low voltages (less than 2 volts) and to be a good conductor.

With magnetostriction, a magnetic field distorts a ferromagnetic material, in other words, made from an alloy comprising magnets. The very low deformation of the material limits this process to sensitive devices, but since we also need a transducer of large size, it is not suitable for micro-robots. The most suitable material is iron-cobalt alloy with or without addition of nickel. The elongation is up to 5 times higher than that obtained with piezoelectric. The force obtained by such a deformation is huge but the extension is barely visible to the naked eye.

The principle of the air pump is more modern, at least in robotics. By blowing air into a container, it is inflated. And sucking the air, it retracts. This property has been used to create a grippable hand, without further action. This implies a network of channels to transfer the air where it is necessary to form a movement of the limb. However, this technique does not seem ideal for a large-scale development.

Now we will see two more appropriate technologies to robotics and more affordable.

Shape-memory

Shape-memory is used in nanotechnology or to operate small mechanisms. Alloy (SMA) subjected to a rise in temperature changes shape and returns to its original shape at ambient temperature. Its effectiveness depends in fact on the speed at which we can produce a temperature rise and cooling. This principle is implemented in the Flexinol.

Flexinol is a wire muscle which retracts at heat and has the advantage of producing a large force and the disadvantage of slowness. Compression distance is around 5%, which does not mimic the action of a muscle, but it is used in combination with a mechanism (the same principle as a pulley or gear box) to increase distance. This material does not return to original size after the action, we must associate it with a spring or a cons-Flexinol to return to position. You can not really use it in robotics due to its slowness but to some parts of the robot and it is inexpensive (less than $ 10 for 1 m of wire supporting 2 kg). The manufacturer is Dynalloy.

The Firgelli actuator

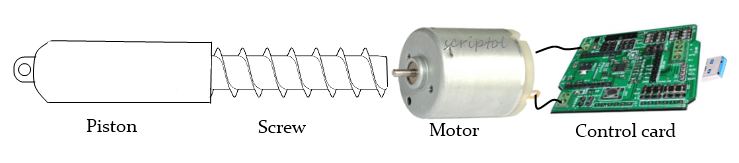

The technology used has nothing to do with what we have seen previously. It is an ordinary electric motor coupled to a screw to convert the rotation into elongation or shrinkage! It returns to its initial position when you reverse the polarity. According to the manufacturer, it is possible to control the actuator from Labview software when it is connected to a USB port using a control card.

The above model L12 which costs a hundred dollars has a robotic use. It is between 5 and 10 cm, weighs 28 g for the lightest model and performs a distance of two inches per second which is very fast. It requires a voltage of 6 V that can be reduced, which then reduces its speed.

Building an actuator

After acquiring a 3D printer, it becomes possible to make its own actuators. This allows you to choose the shape and size desired for the mechanical components, and to choose the motor force and tension.

The construction of an actuator can be inspired form the following simplified diagram:

The current is fed via a control card, which is used to invert the polarity to retract the piston, which is attached to the members of the robot. We can separate the actuator form the member using a wire sliding in a sheath (like the brakes on a bicycle), in which case we must add a wire for the antagonist opposite movements of contraction and extension.

There are Arduino cards to assemble or buy for controlling an electric motor and a dedicated library: AF Motor. Once included, we can use a such code:

#include <AFMotor.h>

AF_Stepper motor(20, 2); motor.setSpeed(300); ...

References

Artificial muscles using polymers. This company produces artificial muscles based on electro-active polymers. Its products are used by vivitouch joysticks to give feedback sensations.

Arduino. Open source platform to build your own control cards.